By implementing the PDCA improvement management cycle together with suppliers, we at the OMRON Group are committed to enhancing sustainability performance in its supply chain.

We also ask critical suppliers to join the Group in efforts to conform to the RBA Code of Conduct. (RBA: Responsible Business Alliance)

| Main activities | Details of activities | Control standards |

|---|---|---|

| Self-assessment | The OMRON Group and a supplier together check the supplier's compliance with CSR Procurement Guidelines, having the supplier make improvements if necessary | Survey once every 3 years minimum targeting all suppliers |

| Assessment based on third-party standards | Third-party organization's audit of a supplier's compliance with RBA*1 Code of Conduct, having the supplier make improvements if necessary | Conduct RBA Corporate Level SAQ*2 surveys for critical suppliers once per year |

| Procurement BCP | Thorough management of the latest information on sources of all parts | Survey newly procured parts from all suppliers and renew data once every year |

| Minimizing procurement risk for individual parts toward the goal of restoring procurement of all parts within a month in case of an emergency. | ||

| Green procurement | To help reduce negative environmental impact across the supply chain by avoiding the use of hazardous substances, the OMRON Group assesses a supplier's implementation of environmental management and regulated chemicals management and certifies as a green supplier based on its criteria | Renew certification once every 3 years, targeting all suppliers |

| Responsible minerals procurement | Survey of materials containing 3TG (tantalum, tin, tungsten and gold) and identifying smelters. Should the use of conflict minerals, financial sources of armed militant groups be found, corrective action will be taken immediately Survey of materials containing cobalt to promote procurement in a manner not to drive environmental destruction and human rights violation. |

Survey once a year |

| Financial evaluation | Evaluating a supplier's financial standing to ensure continuous and stable transactions with the supplier. Mutual deliberation and implementation of improvement measures as necessary | At least once per year |

In asking critical suppliers to answer RBA compliant self-check, we at the OMRON Group offer them learning opportunities, such as opinion exchanges and meetings aiming to make improvements to achieve goals. Especially, with regard to processed product suppliers, we visit their sites as necessary and hold meetings while being updated on their onsite status.

To promote understanding of sustainable procurement amongst our suppliers, we have created training materials and promote e-learning courses.

In fiscal 2022, 61 people from 18 Chinese suppliers (including five critical suppliers) selected by industry sector from among the Chinese suppliers subject to the self-assessment, participated in the training.

In fiscal 2023, we plan to conduct training for all suppliers.

In addition to requesting that suppliers conform to OMRON Group Sustainable Procurement Guidelines, we at the Group also conduct questionnaire surveys, distributing self-assessment sheets to all suppliers and asking them to check their implementation and compliance regarding the guidelines on their own initiative at least once every three years, so as to improve their practices. Our target is to have all suppliers to conduct the assessment.

In fiscal 2022, we requested self-assessments from 478 companies and received responses from a total of 356 suppliers: 126 in Japan, 74 in China, 56 in Asia-Pacific, 35 in the Americas, and 65 in Europe.

| Region | FY2018 | FY2019 | FY2020 | FY2021 | FY2022 | |

|---|---|---|---|---|---|---|

| Plan | 1,154 | 1,376 | 19 | 909 | 478 | |

| Results | 606 | 1,268 | 19 | 603 | 356 | |

| (Details) | Japan | 0 | 735 | 0 | 81 | 126 |

| Greater China | 462 | 472 | 0 | 365 | 74 | |

| Asia Pacific | 0 | 61 | 19 | 11 | 56 | |

| Americas | 103 | 0 | 0 | 93 | 35 | |

| Europe | 41 | 0 | 0 | 53 | 65 | |

| Implemented rate | 53% | 92% | 100% | 66% | 75% | |

In recent years, human rights issues have become a major challenge for companies, requiring them to identify risks in the value chain, conduct more specific assessments to confirm the existence of identified risks, take corrective actions to prevent risks from occurring, and implement remedial measures for risks that have occurred. The OMRON Group is strengthening its HRDD initiatives, and based on the results of a risk analysis conducted in fiscal 2022, we have designated suppliers with production bases in China and Malaysia as targets of our initiatives through fiscal 2024.

We requested more detailed self-assessments and submission of evidence concerning human rights from 18 suppliers selected by industry in China, and obtained responses from all companies. As a result, we confirmed that one company were not giving prior notice of employment conditions, so the company is proceeding with improvements based on the corrective action plan.

We ask critical suppliers to conduct annual self-assessments and self-improvement by using RBA Corporate Level SAQ (Responsible Business Alliance Self-Assessment Questionnaire), a RBA evaluation tool.

In fiscal 2022, 69 critical suppliers, including processed products suppliers, conducted the self-assessment. We also visited our processed products suppliers in China to confirm and discuss improvements.

For suppliers deemed to have sustainability risks as a result of our surveys/audits, we request them to submit improvement plans and take corrective actions. In creating improvement plans, we provide support to all suppliers by holding meetings in which we introduce case studies from OMRON and other companies. Should there be a critical compliance violation, including violation of environmental, social and governance aspects, we have a policy and procedure in place, including actions to review a contract.

During fiscal 2022, we received submissions of corrective actions from 77 suppliers deemed sustainability risks. These suppliers are making improvements based on corrective action plans.

| Risk Category | Contents | Number of companies | Number of companies that implemented improvement |

|---|---|---|---|

| Economic Risk | Suppliers assessed a grade of 4 or 5 (1-5 scale) as a result of initial financial evaluation (secondary evaluation (local audit) deemed necessary) | 34 | 34 (100%) |

| Environmental /Quality Risk |

Suppliers given failing result according to CMS audit | 36 | 36 (100%) |

| Suppliers given a failing result according to PRIMP (line quality audit) | 4 | 4 (100%) |

|

| Social Risk | Suppliers that required improvement in sustainability self-check | 4 (2) |

3* (75%) |

(As of March 31, 2023)

The number of companies in parentheses shows critical suppliers.

In accordance with the OMRON Principles, we at the OMRON Group strive to help create a sustainable society throughout the world by taking dual approaches. One is to supply products and services that contribute positively to the global environment, and the other is to maximize effective use of all management resources. Moreover, we pursue “Green Procurement” of materials, reduction of greenhouse gas emissions (GHG) in the supply chain and reduced resin molding material waste to contribute to lower environmental impact. Here, we proactively adopt materials that do not contain hazardous chemical substances, pursuing procurement that contributes to reducing environmental impact as well as reducing the amount of resin molding material waste.

In green procurement, we specified ecology (reduction of environmental impact) and compliance (observance of laws, regulations, and social norms) as key programs that should be promoted across its supply chain. As such, we certify green suppliers from dual perspectives—establishment of an EMS for environmental management and a CMS for management of chemical substances contained in products.

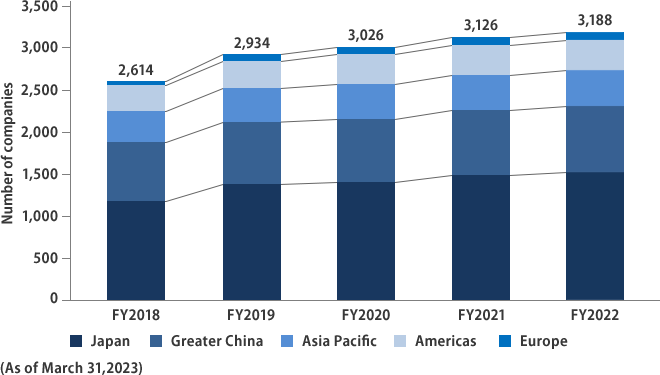

At present, we award or renew certification to suppliers who meet the criteria for green supplier certification revised in 2014. During fiscal 2022, we certified 62 more companies, reaching a cumulative 3,188. We plan to evaluate uncertified suppliers during fiscal 2023.

Green Procurement (Criteria and Documents/Forms)

From the perspective of decarbonization, the OMRON Group is working to reduce GHG emissions in accordance with the GHG Protocol, an international standard, and is also seeking cooperation from its suppliers.

In fiscal 2022, we conducted a survey of 95 key suppliers to determine whether they had set GHG emission reduction targets and the status of their current efforts. As a result, we confirmed that 95% of our suppliers plan to set numerical targets within three years. In fiscal 2023, we plan to monitor each company's GHG emission reductions and initiatives.

We are working with suppliers to reduce the use of fossil fuel-derived resins and eliminate related waste through recycling, looking toward decarbonization and materials conservation.

We are targeting an 840 ton reduction in the amount of reusable resin molding materials we dispose of over the three-year period from 2022 to 2024. We intend to accomplish this by optimizing mold specifications to reduce materials and by adopting processes to reuse waste materials.

In fiscal 2022, we expanded our hot runner technology* and mini-runner technology to reduce resin runners, as well as our recycling technology and management processes to reuse waste materials generated during molding, not only internally but also to at our suppliers.

As a result, we achieved a 281.5-ton reduction in the amount of waste materials, which surpassed our target reduction of 280 tons.

Since 2013, we at the OMRON Group have been engaged in conflict mineral surveys to contribute to a better society. We have established a policy to refuse mineral resources (3TG) mined in the Democratic Republic of the Congo and nine surrounding countries that have continued to violate human rights and damage the environment.

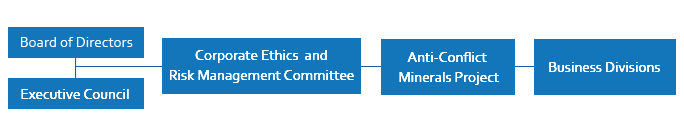

Since fiscal 2013, the issue of conflict minerals has been specified as one of main themes to be deliberated upon and addressed by the Corporate Ethics and Risk Management Committee, which is in charge of devising and promoting counteraction against the OMRON Group's significant risks. As such, the Committee reports the status of conflict mineral use to the Board of Directors and Executive Council every half year. In fiscal 2013, we set up the Anti-Conflict Minerals Project to formulate an annual action plan based on the review of results of the previous year's activities, managing the progress of plan implementations for each supplier and each parts/material category on a monthly basis.

OMRON uses gold as a material for contacts, and gold and tin as materials for gilding terminals and other parts. 3TG is also used as a material in various electronic components and devices that OMRON purchases. Therefore, we have been conducting surveys by using CMRT (Conflict Minerals Reporting Template), the industry standard developed by RMI (Responsible Minerals Initiatives), tracking upstream supply chain.

This survey is based on OECD guidelines for due diligence in risk survey processes. More specifically, we conducted the following steps:

In fiscal 2022, we at the Group examined materials we purchased over the past two years.

The responses were examined thoroughly, and in any case of missing or inadequate answers, we communicated with such suppliers to improve the reliability of responses.

To date, there has been no discovery of usage of conflict minerals for which any association with armed rebel groups is suspected. Should the use of any conflict minerals in OMRON Group products be discovered, we will take corrective action as quickly as possible.

Cobalt is used in lithium-ion batteries that are indispensable for electronic vehicles, mobile phones among other products. The Democratic Republic of Congo is the largest cobalt producer in the world, and there is a concern pointed out about manual mining in the country with poor working conditions and child labor.

We have a basic group policy in its Sustainable Procurement Guidelines that bans any forms of forced and child labor, and promotes cobalt procurement in a manner not to drive environment destruction and human rights violation.

We have been conducting survey for lithium ion secondary batteries, which have come under scrutiny around the world, using the RMI (Responsible Minerals Initiative) Cobalt Reporting Template.

Since fiscal 2015, we have provided one-on-one briefings for suppliers whom we ask for cooperation in the survey for the first time as the OMRON Group.

In April 2011, OMRON joined the Responsible Minerals Trade Working Group organized by the Japan Electronics and Information Technology Industries Association (JEITA), actively collecting information and promoting partnerships with industry organizations. Since fiscal 2015, OMRON participates in the planning and management of conflict mineral investigation conference meeting hosted by the Working Group to promote dissemination of conflict minerals efforts across supply chains of the industry as a whole.

Developing fine-quality products to contribute to society through business is one of the most important social responsibilities of a manufacturer. At the OMRON Group, we believe that it is equally important to provide a stable supply of products, even in the case of a contingency. Based on the awareness that a disaster can happen at any moment, we have been promoting procurement BCP* since fiscal 2011.

We established a system to confirm the impact on our business within 24 hours of a contingency, striving to improve management in these cases. In addition, we manage potential procurement risks for parts and materials by classifying them into three ranks. Efforts are now focused on minimizing procurement risks by taking measures such as keeping certain parts/materials in stock. The goal is to build a system to resume procurement of all parts within a month in the event of a disaster.

In fiscal 2017, we designed and introduced a central inventory control system to manage the stock of highest-risk parts in a unified manner at the Group.

Although the recent spread of COVID-19, natural disasters such as earthquakes and floods, and accidents such as fires have affected many of our suppliers, we have quickly identified risks based on local production area information for components we manage, promptly holding meetings participated by procurement staff from across our company. We also held discussions about, and implemented measures with, our suppliers. In this way, we have prevented significant supply problems to date. For parts facing shorter supply, the head office purchasing department takes the initiative in making advance arrangements and securing inventories in an effort to minimize the impact on business.

We at the OMRON Group believe that there are essential factors to practice the OMRON Principles and realize sustainable supply chain: To eliminate human rights violation risks within the Group, and create a work environment in which everyone can work in a safe and healthy manner both physically and mentally, and demonstrate his/her best performance.

The idea applies not only to employees and temporary workers at the OMRON Group, but also to employees of on-site contractors working at the Group sites. When their employees start working within our sites, we communicate with them about our human rights policy and human rights related initiatives such as access to remedies open to on-site contractors’ employees, which include human rights consultations and compliance hotline programs. Additionally, targeting contractors’ on-site leaders, we offer them human rights training sessions so that they can share the learnings with the rest of their on-site members as well. Contractors are defined in RBA standard as one of the next tier major suppliers, and we at the OMRON Group are furthering our commitment accordingly.